Home • Application Experience and Markets Served • Why use protective coatings on my heat exchanger?

According to the leading corrosion control organization, NACE International, corrosion is one of the largest single costs in the US economy. NACE further estimates that companies could save 15 – 35% of these costs by implementing corrosion control measures.

According to the leading corrosion control organization, NACE International, corrosion is one of the largest single costs in the US economy. NACE further estimates that companies could save 15 – 35% of these costs by implementing corrosion control measures.

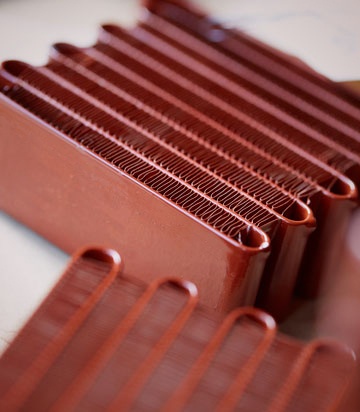

Every coil placed in an environment where the coil is exposed to chemicals, severe weather, or salt spray should have a protective coating applied before corrosion begins. The best time to apply coatings is before the unit is put into service.

At Heresite, we estimate that using a high-performance coating to protect the coil can more than triple a coil unit’s life. Ideally, coatings should be applied before coils are installed into a unit; depending on the environment, corrosion can begin in as little as the first year of equipment use.

When your company thinks about its HVAC-R coils and heat exchanger equipment, ask yourself:

The use of protective coatings for corrosion management is a key part of sustainable business practices combining the benefits of reduced environmental impact, increased profitability, and demonstrable social responsibility.

Applying a protective coating can reduce costs related to:

The use of protective coatings can improve coil unit performance including heat transfer reduction, optimized fan power requirements. Protective coatings can also help protect coils in areas requiring sanitization and can make cleaning equipment easier.

Plus, corrosion protection can prevent customer service and public relations issues related to equipment failure. For example, equipment failure at a wastewater treatment facility, an airport, or a manufacturing plant can impact residents of the greater community in which the business operates.

Although cost savings from corrosion control are often not immediately obvious, applying a protective coating to your HVAC-R and industrial equipment will, over time, reduce maintenance costs, cut down the need for frequent inspections, reduce production downtime due to unexpected failures, optimize unit performance, and can even help improve public relations.

Learn about the variety of HVAC-R protective coatings offered at Heresite.