Be it blizzards or heat waves (and anything in between), your HVAC system works hard year-round to keep you comfortable. Protecting your heating and cooling equipment is easier than you think.

Be it blizzards or heat waves (and anything in between), your HVAC system works hard year-round to keep you comfortable. Protecting your heating and cooling equipment is easier than you think.

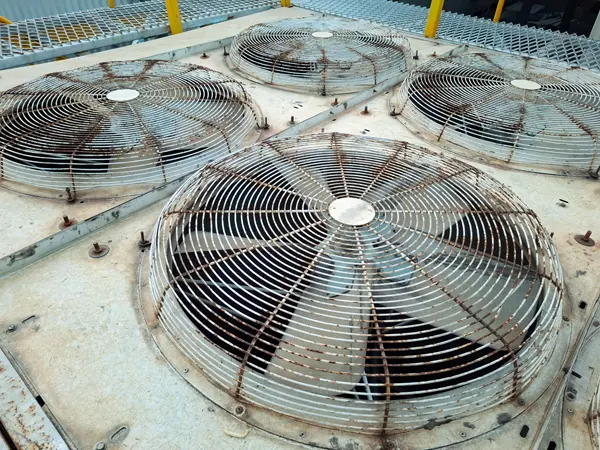

Protective coatings are one of the most effective ways to extend the life of your HVAC system, especially in environments where moisture, salt, debris, or chemicals can cause corrosion. Over time, unprotected coils and metal surfaces begin to break down, leading to costly repairs or premature failure. Here are three major warning signs your system needs protective coatings.

What you don’t want to see:

Corrosion eats away at metal surfaces, limiting airflow while reducing your system’s performance. If it’s left untreated, it can cause all kinds of leaks, coil failure, or a complete system breakdown. And once corrosion sets in, it spreads quickly.

Have your exposed HVAC components checked out regularly, especially in harsh environments like coastal or industrial settings. Applying a high-quality anti-corrosive coating to coils and metal parts provides a durable barrier that prevents rust from forming from the get-go.

When coils or other heat exchange surfaces are exposed to the environment, a thin layer of oxidation forms on the metal. This buildup acts as an insulator, restricting heat transfer between the air and the refrigerant.

As a result, your system starts working harder and running longer to achieve the same outcome. You may notice things like:

Over time, this extra workload can shorten the life of your equipment. A protective coating helps stop corrosion before it starts, keeping heat transfer surfaces clean and efficient so your system runs smoothly and uses less energy, saving you money.

Regular repairs and early component failures in HVAC equipment point to underlying issues, which can shorten your system’s lifespan. These problems bump up operational costs and downtime while reducing overall reliability and performance. Problems you should look out for:

Have the conversation with your HVAC tech about protective coatings for your specific environment. If your system operates in harsh conditions, near saltwater, in humid areas, or around chemical exhaust, protective coatings are a must. Systems without protective coatings can require expensive part replacements years earlier than expected.

Investing in protective coatings is one of the best ways to protect your HVAC system. And your pocketbook. With regular inspections, preventive maintenance, and proper coatings, you can avoid major repairs, lower operating costs, and keep your system performing like new for years.

Heresite Protective Coatings is the leader in corrosion prevention. Our coatings have been used for decades to provide lasting protection for coils and other components in many applications exposed to corrosive environments. Contact us today, and let’s talk about how we can help extend the life of your HVAC equipment. Because in the coatings industry, there really is NO EQUAL.